OUR PRODUCTS

The company has a number of experienced engineers in rubber machinery, the introduction of Taiwan technology, with production equipment and attentive after-sales service to provide customers with energy-saving products

Taixing Ruixing Rubber Machinery Co., Ltd

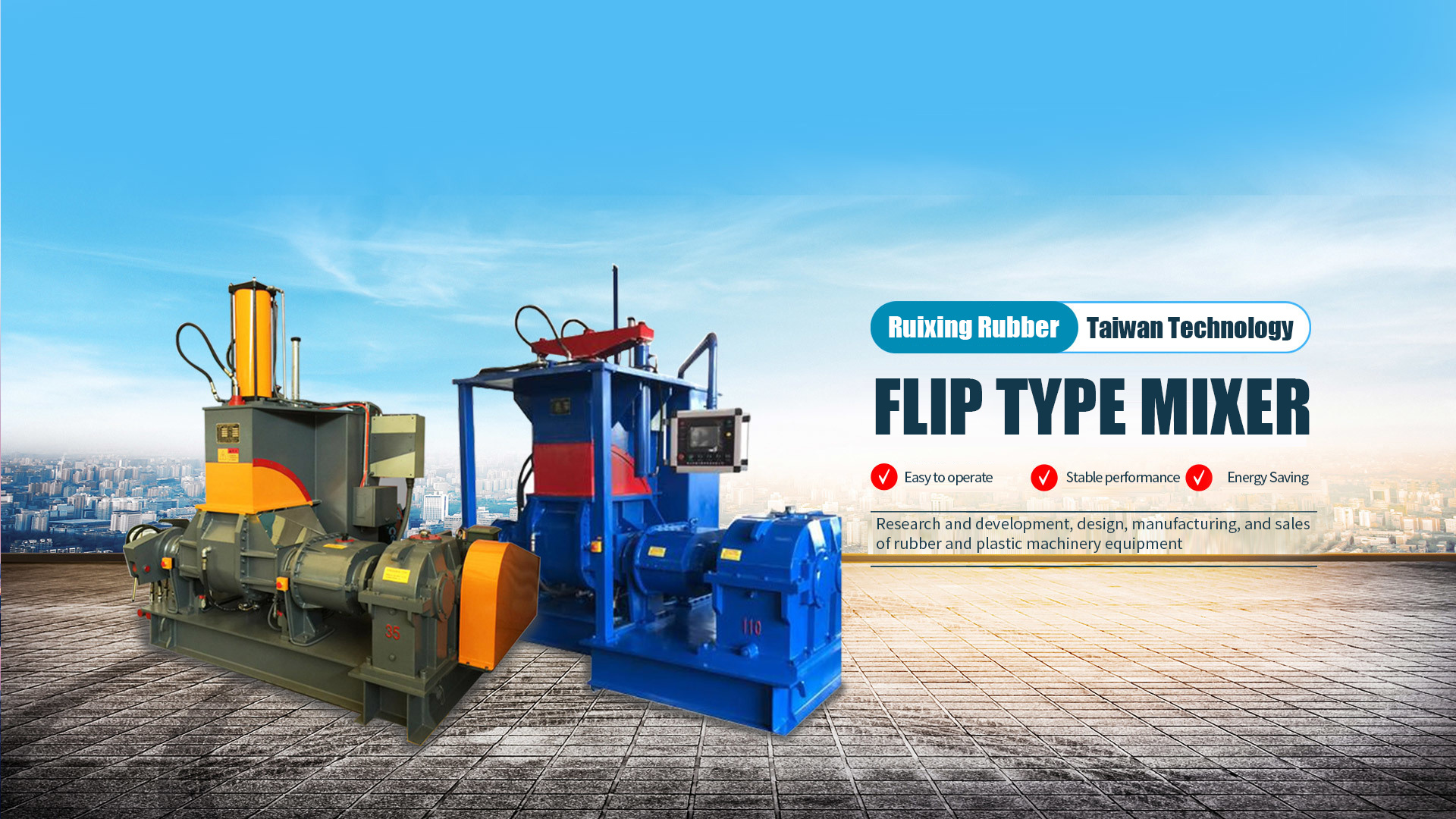

Taixing Ruixing Rubber Machinery Co., Ltd. is a professional manufacturer dedicated to the research and development, design, manufacturing and sales of rubber and plastic machinery and equipment. The company has a number of experienced engineers in rubber machinery, the introduction of Taiwan technology, with production equipment and attentive after-sales service to provide customers with energy-saving products.

The company's products mainly include: rubber and plastic pressurized kneading machine, open rubber mixing (plastic) machine, EVA/TPR/PVC/color masterbatch high-speed granulation production line, rubber extruder, automatic rubber filter, calender, rubber cutting machine, mixing production line, extrusion tablet press, extrusion production line, calendering production line, etc. The products mainly serve the tire industry, seal industry, hose and adhesive tape industry, cable industry, medical bottle stopper industry, and the production of EVA, TPR, PVC, masterbatch, low-smoke halogen-free cable blocking materials, etc. The processed products are widely used in various fields such as rubber electronic parts, shoe materials, auto parts, conductive rubber, industrial oil seals, oil rings, packaging, sports equipment, medical devices and various utensils.

Culture

A professional manufacturer dedicated to R&D, design, manufacturing and sales of rubber and plastic machinery

Honor

Introducing Taiwan technology, providing customers with energy-saving products with production equipment……

Workshop

With strict quality management, the quality of products is created

Join Us

As a developing company, we hope to follow the trend and constantly attract people with ideals and ambitions to join us

News Center

Company News

Always adhere to the quality of development, quality of survival principle, continue to improve Ruixing rubber products and services

Industry dynamics

Sincerely welcome the national seed industry colleagues and friends to visit the guidance

12

/

14

News dynamics

12

/

14

News dynamics